| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : OEM

Model Number : 4V210-08

Certification : CE、ISO

Place of Origin : China

MOQ : 200pcs

Price : Negotiation

Payment Terms : T/T, PayPal, Western Union

Supply Ability : 100000pcs per month

Delivery Time : Negotiation

Packaging Details : Box, Carton, Pallet

Material : aluminum alloy

Port size : 1/4''

Pressure : Medium Pressure

Media : air

Connection : Thread(NPT

Working pressure : 0.15-0.8MPa

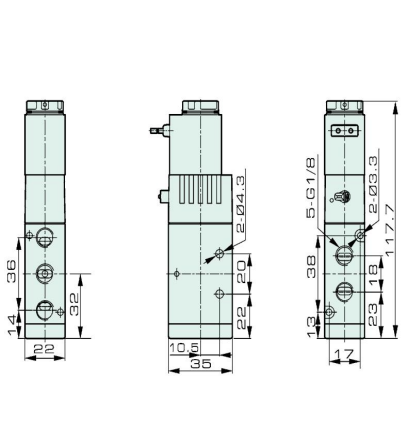

200 Series 1/4'' Two-Positon Five-Way Pneumatic Solenoid Control Valve 4V210-08 Working Pressure 0.15-0.8MPa

The Main Features of 4V210-08 as Follows:

1. Pilot mode: external and internal optional;

2, the sliding column structure, good sealing and sensitive;

3. Three-position solenoid valve has three central functions to choose from;

4. The double-headed two-position solenoid valve has a memory function;

5. The inner hole is processed by special process, the friction resistance is small, the starting air pressure is low, and the service life is long;

6, no need to add lubrication;

7. It can integrate the valve group with the base to save installation space;

8, with a manual device, which is conducive to installation and commissioning;

9, a variety of standard voltage levels are available.

| Product Name | Model | Type | Material | Working Voltage | Operating Pressure | Effective Area | Power Consumption | Insulation Grade |

| Pneumatic Solenoid Valve | 4V130C-06 | 2 Position 5 Way | Aluminum Alloy | DC12V DC24V AC110V AC220V | 0.15-0.8MPa | 12mm² | AC:2.5VA DC:2.5W | IP65 |

Installation and usage

1. Check whether the components are damaged during transportation before use, and then install and use;

2. Please pay attention to the direction of gas flow and whether the tooth shape of the nozzle is correct during installation. The medium must be filtered by a 40um filter element;

3. Please pay attention to whether the installation conditions meet the technical requirements (such as "voltage", "operating frequency", "working pressure", "operating temperature range", etc.), and then install and use;

4. Pay attention to the direction of gas flow during installation,P is the inlet, A(B) is the working port, and R(S) is the exhaust port;

5, try to avoid the use of vibration in the environment, and pay attention to low temperature antifreeze measures;

6. When connecting the pipeline, please note that the winding of the stop drain belt shall not exceed the end face of the joint tooth. Please pay attention to removing dust, iron chips and other dirt in the pipeline joint to avoid impurities or foreign matters entering the valve body.

7, please pay attention to dust, it is recommended to install muffler or muffler throttle valve in the exhaust port. Remove when not in use should be installed in the air inlet and outlet dust jacket.

8, when the whole machine debugging, it is recommended to use the manual device debugging, and then debugging.

Feedback

We maintain high standards of excellence and strive for 100% customer

satisfaction, Feedback is very important We request that you contact us

immediately BEFORE you give us neutral or negative feedback , so that we

can satisfactorily address your concerns .

It is impossible to address issues if we do not know about them

If you have any question about any type solenoid valve or its fittings, just contact us without any hesitation.

|

|

200 Series 1/4'' Pneumatic Cylinder Valve 4V210-08 Working Pressure 0.15-0.8MPa Images |